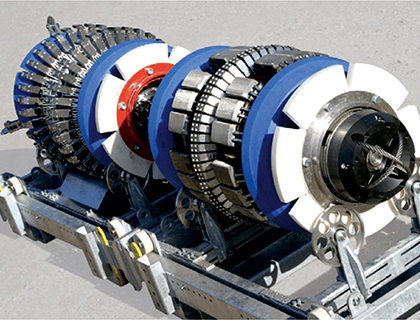

Technology based at Villary effect, tool has new generation of ferrosonde sensors detects changes in the magnetic field. Technology could detect: Metal loss from 10%, corrosion, defects related to metal loss, changing the pipeline geometry, stress-deformed states, unauthorized tie-ins and repair sites

Remote measurements of magnetic field anomalies caused by defects of various nature

Monitoring inside pipeline with a set of various sensors

Non destructive testing by traditional methods

| PARAMETER | SPECIFICATIONS |

|---|---|

| Type Of Sensors (Primary Transducers) | The Latest Generation Of Fluxgate Sensors |

| Amount of measured parameters of the magnetic field | 12 |

| Types of detectable defects | Metal loss from 10% |

| Crack-like defects | |

| Discontinuity | |

| Weld joints defects | |

| Change in geometry | |

| Anomalies Of Stress-deformed State (sections With Sags, Deflections, And Landslip Phenomena) | |

| Other defects cause changes of the magnetic field | |

| Determination of pipeline bedding depth | Up to 15 diameters of the inspected pipeline |

| PARAMETER | SPECIFICATIONS |

|---|---|

| Min/Max diameters of the pipelines inspected | 8in – 60in (200-1420 mm) |

| Min/Max pipeline wall thickness | No limitation |

| Type and presence of coating and cathodic protection | No limitation |

| Min/Max pressure of fluid in pipeline | 5 bar (75 bar) / no limitation |

| Depth/size of detectable metal loss | Starting from 10 to 100% of pipe wall thickness / from 1.5 mm long (single pitting) |

| Length/opening of detectable crack-like defects | From 8 mm / 300 µm |

| Rate of survey | Up to 6 m/sec |

| Requirements preparation of the surface and changes in pipeline operation mode | Not required |

| Intersection with underground lines/cables/metal objects | Will be excluded from analysis as interference points |

| SPEED OF CONDUCTING SURVEYS | MEASUREMENT TYPE | ACCURACY | COST | ADDITIONAL REQUIREMENTS | |

|---|---|---|---|---|---|

| Inspex | 4 km/h | Non-contact (up to 10 Pipe Diameters) | 90-98% | Low | No Access Required |

| Contact Inspection | 30-50 m/h | Contact (outer surface of the pipe) | 95-98% | Low | Access To The Pipe Body Is Required |

| In-line Inspection | 4 km/h | Contact (inner surface of the pipe) | 90-98% | High | Special Equipment Of The Pipeline Is Required; Violation Of The Pipeline Operation Mode Is Required |